The tire production management warning system

The tire production management warning system

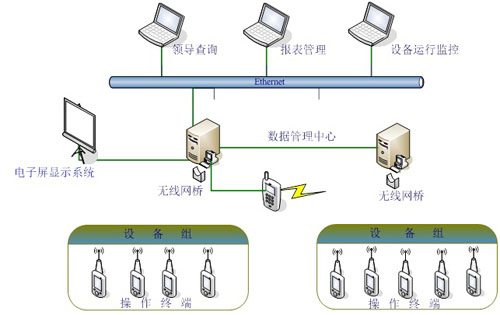

With the development of information technology workshop production of manufacturing enterprises, the increasingly high demand for the various types of state have continued to increase the productivity and efficiency of operation and maintenance of the equipment. Most of the production workshops are manual records and statistics of the various types of state, only the use of advanced data management platform in order to realize the large acquisition of device status and statistics. Of the key technologies to achieve these state management device status automatic collection and classification management, network structure using a combination of wireless and wireline communications, the state high-speed data acquisition, using different management strategies for different status information, the data flow for effective analysis and processing.

Node data acquisition and confirmation of the status of the wireless network to all devices, network communication transmission efficiency, take the initiative to report the communication server polling transmission mechanism reduces network congestion and to ensure that the device status reported accurately correct. Industrial Ethernet technology to ensure the dissemination and sharing of all process data to ensure that departments at all levels within the enterprise can view device status information in real time, and according to the different functions to achieve the classification of the data stream management.

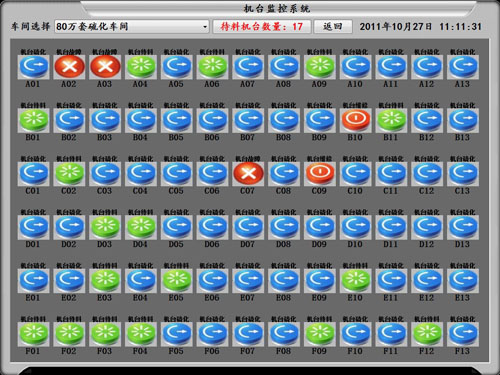

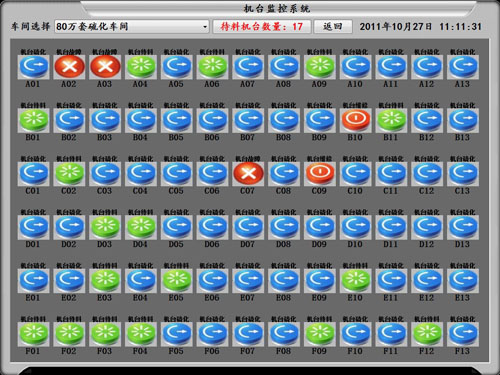

Data management platform data unit linear queue mechanism for handling real-time storage of all device status, concurrent processing of all process line equipment like data, and in accordance with the automatic sorting of the status of the device level, to ensure that the process management norms and complete. Characteristics for the device status, device status, category management, using a variety of data and notification mechanism in a variety of ways, including the LED screen, multi-monitor, multi-level client as well as text messages and phone calls.

Site operator terminal:

The site operator terminal using high-performance ARM processor, LED screen display, provides electrical input interface, complete signal acquisition, display and send. The following figure shows the processing flow of the program.

1, the use of industrial network wireless band for free network communications, network communication delay short, collision avoidance protocol algorithm, to ensure the reliability of data transmission.

2 8-channel digital input channels, the completion of the automatic acquisition of equipment status signals, while providing other electrical input to complete the input of user-defined state.

3, according to the state rules pre-set by the user, device status interlock to ensure uniqueness and accuracy of the device status of the input signal.

The regional range equipment failure alarm, the area of real-time multi-tasking mechanism to complete device failure alarm, and to ensure that the concurrent processing of data communication interface displays.

Data management center:

Data management center for a group of servers, complete device status information acquisition, processing, display and sharing functions, is the core processing section.

1, the data management center terminal for the one-to-many relationship with field terminal, system uses multi-thread technology to achieve high-speed data acquisition, to ensure that the server response within one second of the operating terminal to issue commands to ensure that all terminal data in real time and accuracy.

2, the judgment of the importance of all states, in order to prevent the misuse of field operatives, data center using a linear queuing technology to confirm the importance of all states, to do adaptive processing for all state, to ensure that the status of the order of execution for the first-in-first-out.

In real time to ensure that the client browser field device status information, the system provides many different types of data storage capabilities. According to the data stream type of business, the system provides real-time libraries, historical library, statistical library with logging data can be stored.

4, the data management center according to predefined rules and customer type data determination to ensure that production data, status data and the co-processing of statistical data. Equipment failure information screen is displayed, transmitted by the communication module to the specified mechanic phone, and to provide an alarm call function, to ensure that equipment failures occur within 10 seconds, the maintenance man to the device serial number and fault detail.

Data management center by obtain Treasury raw materials library component information, combined with the state of repair of the equipment, and automatic generation of machine maintenance expense reports, and the monthly automated clearing equipment costs.

Data management center to be expected according to the state, other tooling state running, equipment operating efficiency and production cycle of the automatic statistical data to improve the process.

5, the data management center with a large database storage device state data, the use of high-performance storage process is complete, high-capacity data retrieval, all workstations within the network in real time browsing device data, device status display time interval difference of less than 3 seconds historical data and statistical data query can also be completed quickly.

Data management center according to the data requirements of the enterprise ERP system, generate reports automatically uploaded to the specified FTP directory, according to the set time interval to complete the interaction of the enterprise information.

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Hotline:400-818-6918

Hotline:400-818-6918

Web:www.nessesen.cn

Web:www.nessesen.cn